Energy Optimization

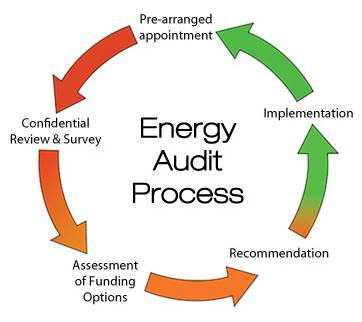

Increasingly limitations of energy resources in the world, have made governments assess energy policies to prevent energy wasting. This can be done through ENERGY AUDITING

Energy Auditing Types

- Walk-Through Energy Auditing

- Preliminary Energy Auditing

- Detailed Energy Auditing

|

|

Abilities

- Energy audit for power plants, industrial units and buildings

- Thermal energy audit & fired equipment analysis

- Distribution system analysis

- Process audit

- Power quality study

- Design and engineering

- Projects management

- Waste heat recovery

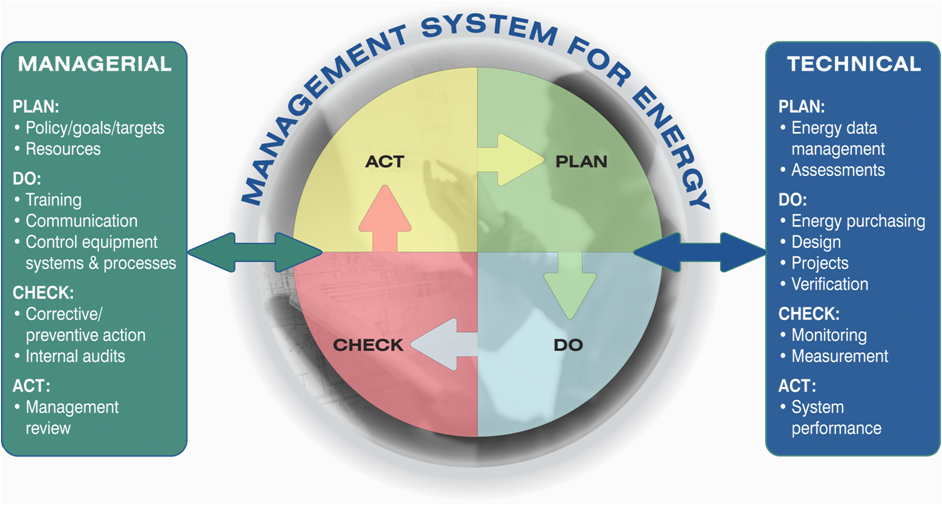

Energy Management

Energy management is the process of monitoring, controlling, and conserving energy in an industry, building or organization to ensure that the power stations and renewable energy sources generate enough energy to meet demand.

Abilities

- Primary evaluation, monitoring and audit of energy production and consumption

- Planning and organization of energy management projects

- Advice for the establishment of energy management principles

- Energy purchase planning with the most appropriate prices

- Planning for energy efficiency in design, processes, buildings, equipment and ensuring optimum performance

- Determine clear criteria for investment in energy

- Proper training of personnel about energy management

- Increasing staff awareness and training them for saving energy

- Increasing staff awareness and creating a culture of energy saving

- Specify responsibility of energy use

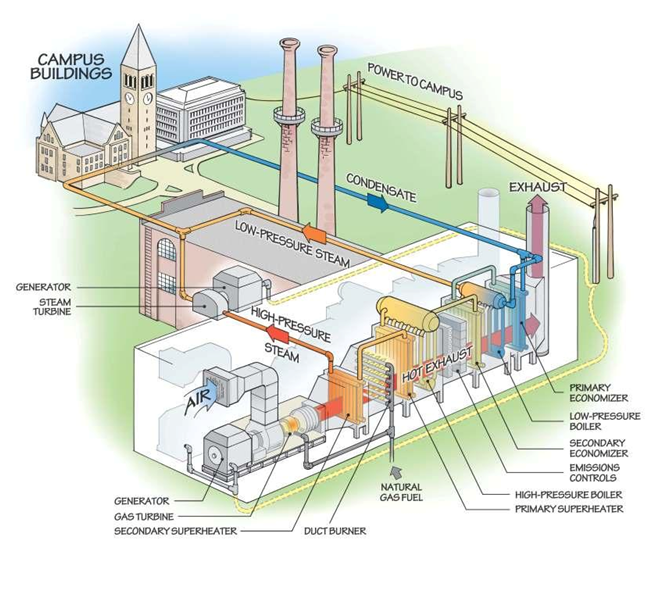

CHP & CCHP (Combined Cold, Heat & Power)

CHP & CCHP offer energy and environmental benefits over electric-only and thermal-only systems in both central and distributed power generation applications. These systems have the potential for a wide range of applications and the higher efficiencies result in lower emissions than separate heat and power generation.

Abilities

- Basic & Detailed Engineering Services

- Selection of type and size of primary and auxiliary power plant equipment

- Conceptualization of Civil and Structural works requirement

- Estimation of project cost and unit generation cost

- Plot Plan and Equipment Layouts for various buildings and areas

- Selection and specifications of Power Plant Equipment

- Design of P &I diagrams

- Design of power evacuation system

- Design / Sizing and specification of Electrical equipments

- Electrical system study including Relay Co-ordination

- Architectural, Civil and Structural design

- Procurement, Construction and Commissioning Supervision Services

Expansion Turbine

Turbo expanders are used in all segments of the oil and gas industry to produce cryogenic refrigeration, while increasing the facility’s energy efficiency and reducing its CO2 footprint. A turbo expander, on the other hand, is a pressure let-down device that produces cryogenic temperatures while simultaneously recovering energy from a plant stream in the form of shaft power that can be used to drive other machinery such as a compressor. Expansion turbines can be used in many different applications, including gas processing, air separation, power generation, energy recovery, jet engine testing and cryogenic refrigeration.

Abilities

|